Artevet Therapeutics manufactures a diverse range of dosage forms for animal health,

formulated under stringent GMP protocols and global regulatory standards.

Facilities

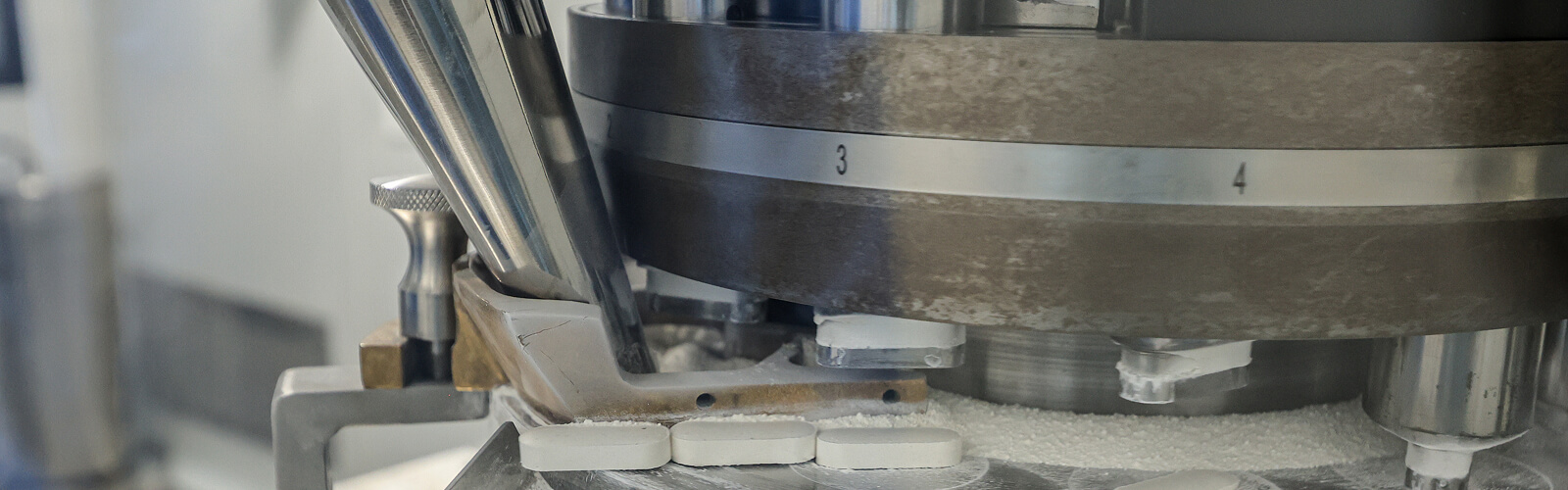

Effervescent Tablets

Our facility is equipped to produce effervescent tablets for both disinfection/sanitation and vitamin and mineral combinations. Our comprehensive production line features a blending facility, fluid bed dryer, high-speed compression machines, and a fully automated tube packing line for efficient packing, labeling, and shrinking.

Oral Solid Dosages (Tablet/Bolus/Chewable)

Oral Solid Dosages (Tablet)

Our production line is capable of producing up to 400,000 tablets/boluses per shift. Equipped with high-speed compression machines, automated dryers, a paste kettle, and various blenders, the line is specifically designed to handle light-sensitive materials, ensuring quality throughout the entire process up to the blister machine.

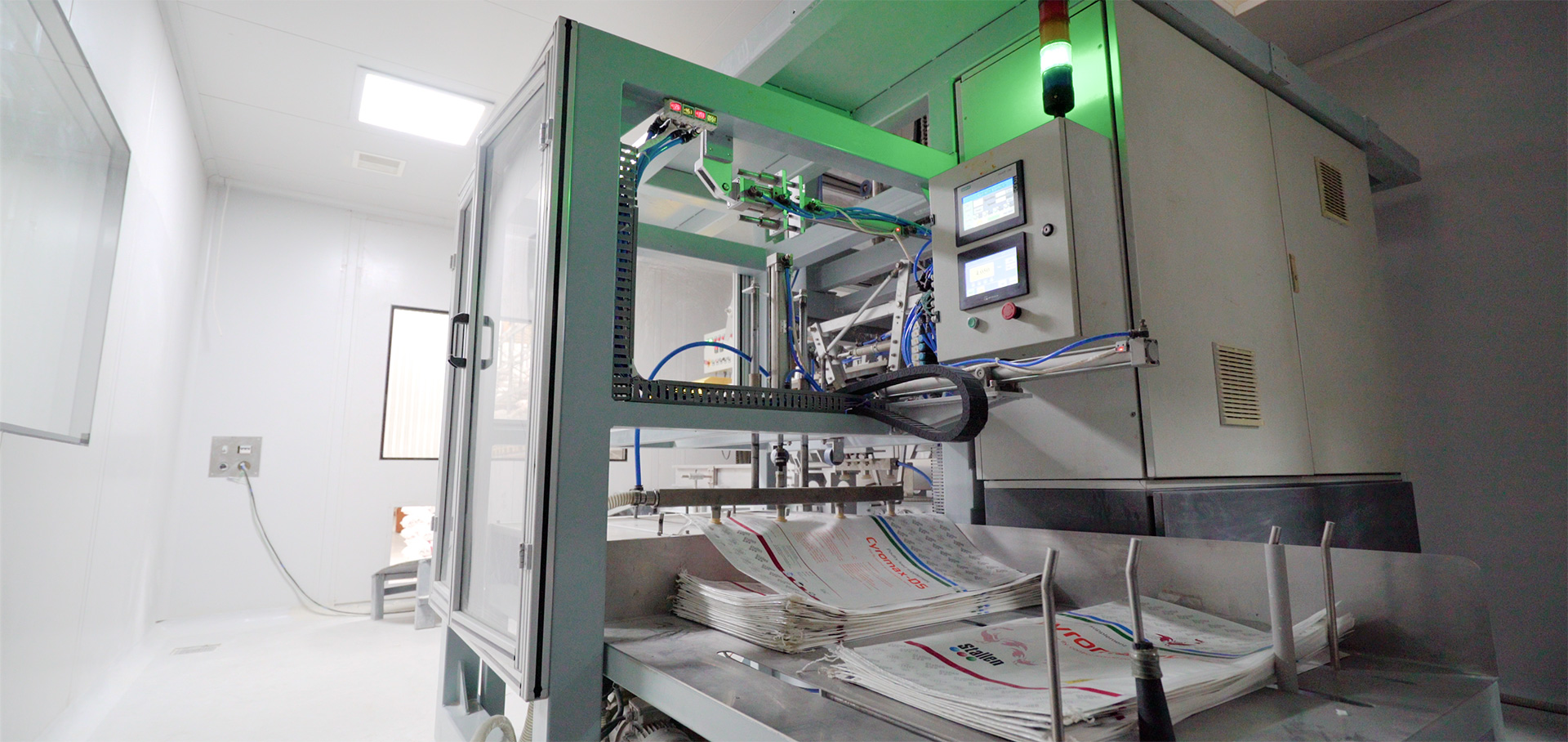

Oral Solid Dosages (Powder)

Oral Solid Dosages (Powder)

Our dry granulation process features a fluid bed dryer and an octagonal blender, complemented by an accurate form-fill-seal pouching machine. This setup allows us to produce sachets or pouches ranging from 50g to 1kg with precision and efficiency.

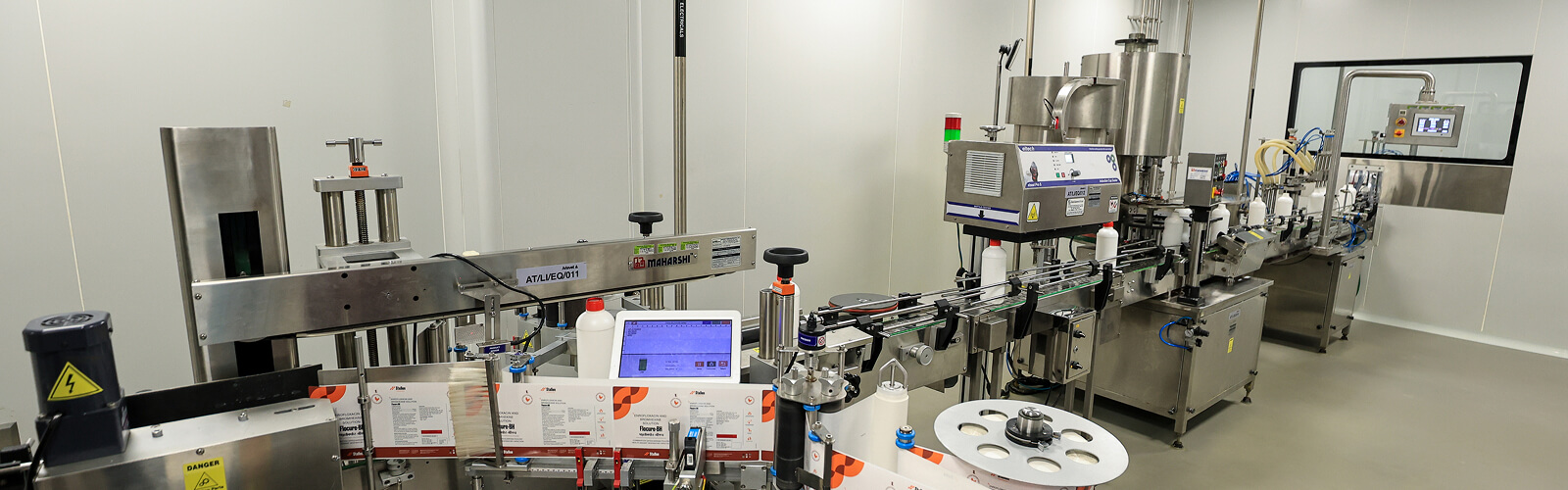

Oral Liquid

Oral Liquid

Our production system features a 2000L batch size for oral liquids, drenches, and suspensions, utilizing a PLC-operated setup and an automated transfer line to ensure seamless movement from raw material to finished product without human touch or air exposure. Our fully automated bottling plant manages air wash, filling, capping, and labeling for bottle sizes ranging from 50ml to 5L, with an impressive output of up to 2000 bottles per hour.

Topical / External Liquid

Topical / External Liquid

Our facility is equipped to produce effervescent tablets for both disinfection/sanitation and vitamin and mineral combinations. Our comprehensive production line features a blending facility, fluid bed dryer, high-speed compression machines, and a fully automated tube packing line for efficient packing, labeling, and shrinking.

Beta Lactam Oral Solid Dosages & Ointments / Intra Mammaries

Beta Lactam Oral Solid Dosages & Ointments / Intra Mammaries

In a separate building to prevent cross-contamination, we prepare beta-lactam and cephalosporin products in oral solid dosage forms, as well as ointments and intra-mammary products in tube packaging.